The Cremona production site is a very modern industrial works, which, thanks to its technological, environmental and ergonomic conception, can be defined as a new system for steel manufacturing.

It is Europe’s first and the world’s second mini-mill for the manufacture of flat rolled steel.

Since 2009 it has had two complete lines for the production of steel in the form of hot rolled coils, each fitted with its own melt shop for the production of liquid steel and an integrated cast-rolling line (ISP and ESP).

With the second plant it has achieved an epoch-making innovation, the continuous cast-rolling process called Arvedi ESP - Endless Strip Production (patented in the most important countries).

The particular plant equipment allows the special products to be produced flexibly and economically, making it the strong point of the works.

The hot rolled coil is further finished on pickling, cold rolling, galvanizing and painting lines, which, together with the slitting lines, process a considerable share of production, supplying customized products and speedy service to end users.

Production capacity is about 4 million tonnes/year, main production being:

Hot rolled galvanized and pre-painted coils

Formats deriving from slitting into strips and sheets

The industrial complex is organized into a hot area and a cold one.

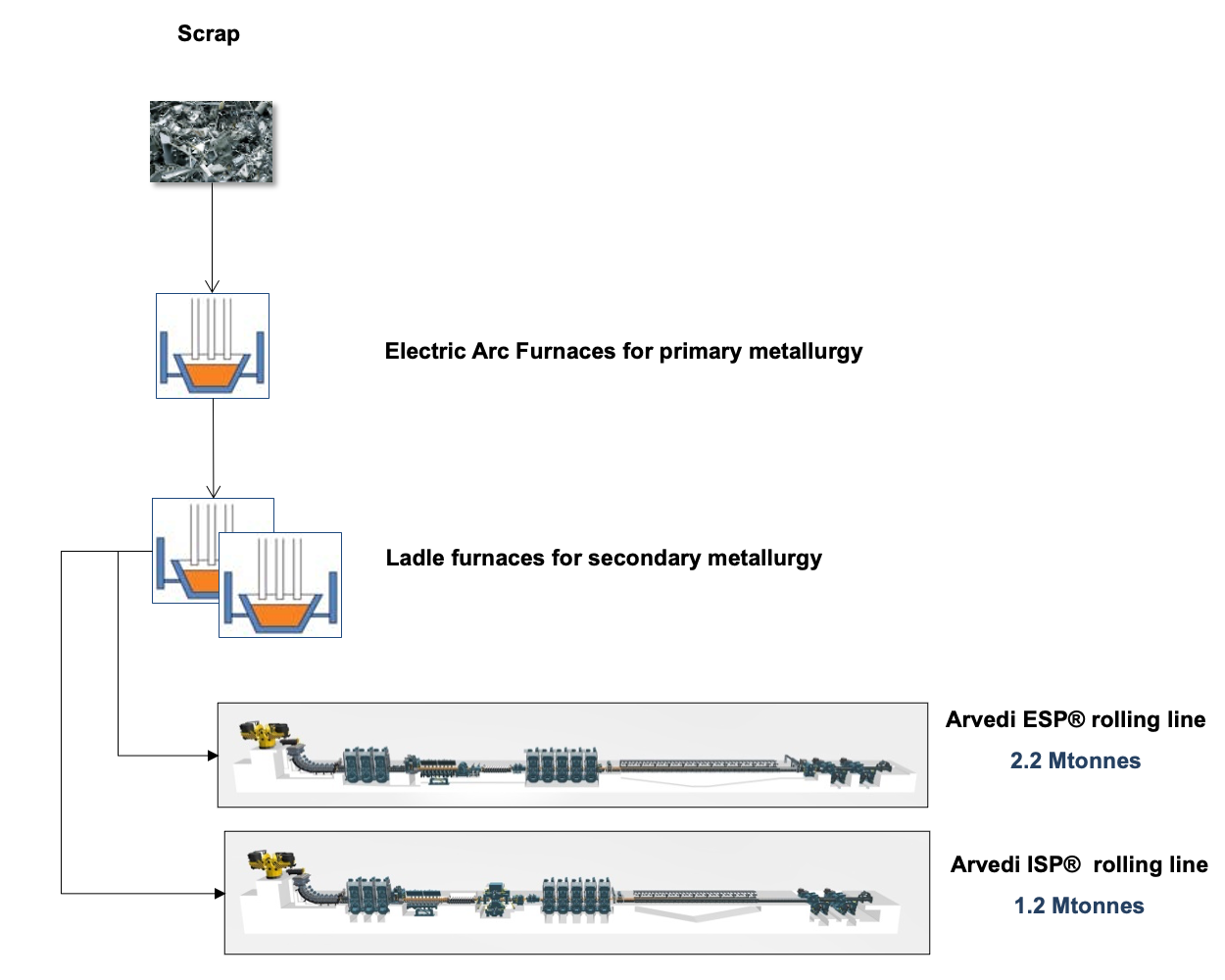

HOT AREA PRODUCTION FLOW CHART

The hot area includes:

- 2 scrap yards, each one dedicated to an EAF

- 2 EAFs for primary metallurgy, one fitted with Consteel ® technology

- 4 ladle furnaces for secondary metallurgy

- 1 VOD (Vacuum Oxygen Decarburization) furnace

- 2 rolling mills based on Arvedi ISP/ESP ® technology