The site dedicated to cold rolled products for special applications and the only works in Italy for the production of electrical steel

Through its production site in Trieste, Acciaieria Arvedi can offer cold rolled products in a wide range of grades and sizes.

The innovative hot rolling process in Cremona allows it to be supplied with coils having excellent geometrical characteristics for the production of cold rolled steels with unique characteristics and repetitive and constant properties.

Cold rolling at the Trieste works preserves the fine grain homogeneous structure of the base steel produced in Cremona and therefore its high formability characteristics.

The works currently employs 350 people and occupies an area of about 350,000 m2.

The site has a logistics terminal and dock overlooking the sea for the collection of raw materials and shipping of finished products, an internal railway plus a railway junction with the RFI network.

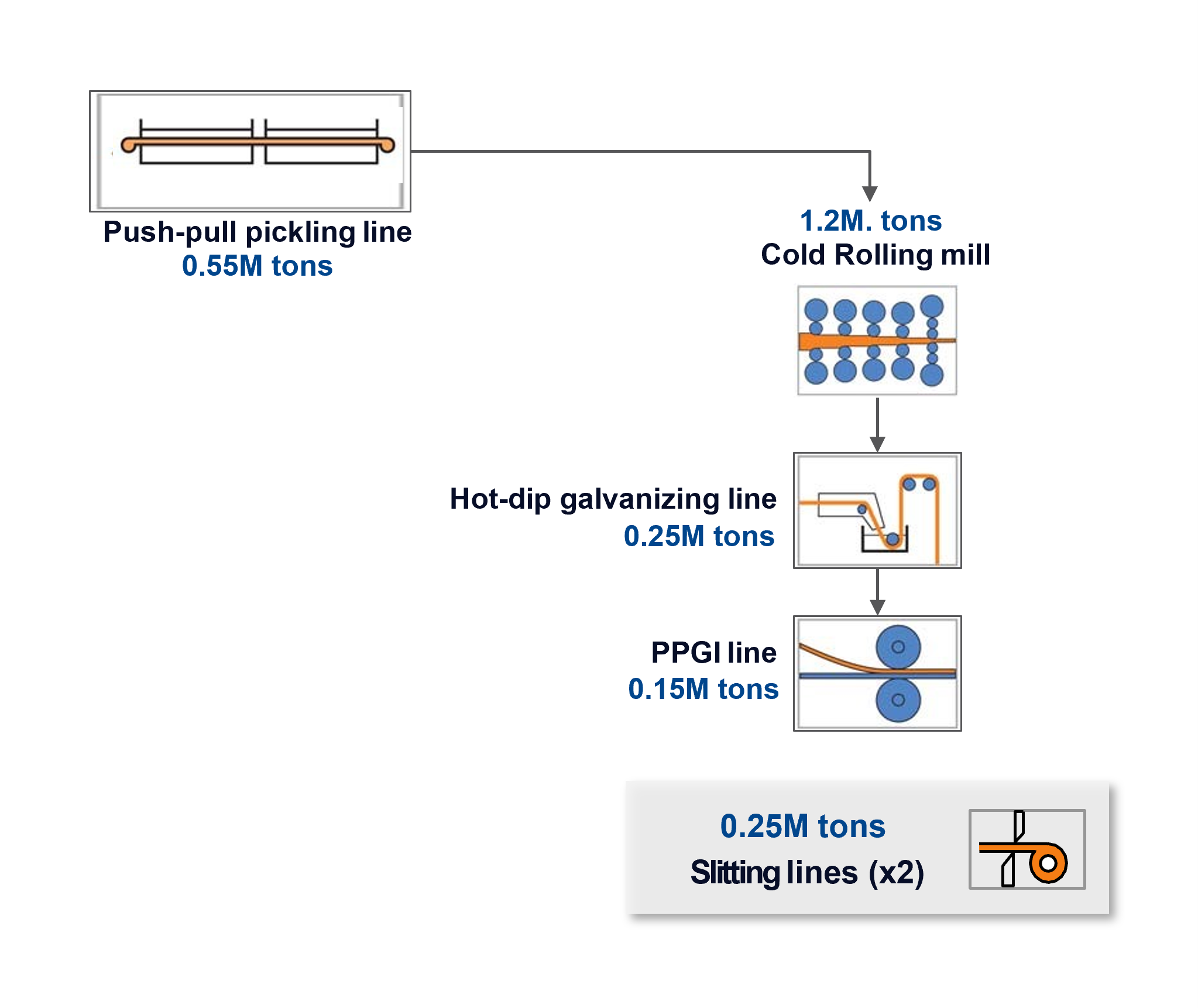

Cold rolling production capacity is 800,000 tonnes/year, mainly of:

Cold rolled coils

Cut-to-measure formats

ENERGY EFFICIENCY

In the course of 2017, a system was installed for recovering heat from the hot fumes exiting the coal distillation process (coking plant) to produce steam to be introduced into the current industrial hot water (90°C) distribution system, replacing the steam coming from the works electrical power station.

In 2018 a plant was installed for the recovery of the hot air exiting the fans from the sinter mix cooling process. The heat recovered is used to produce industrial hot water (95°C) for use in the pickling plant foreseen for the cold rolling area.

These are energy-efficiency operations which will allow a reduction of CO2 emissions of more than 16 thousand tonnes/year.