History

Acciaieria Arvedi started up in 1992 as the prototype of a new steelmaking model for steel coil production, capable of producing thin and quality materials in small lots at competitive costs and with highly flexible production.

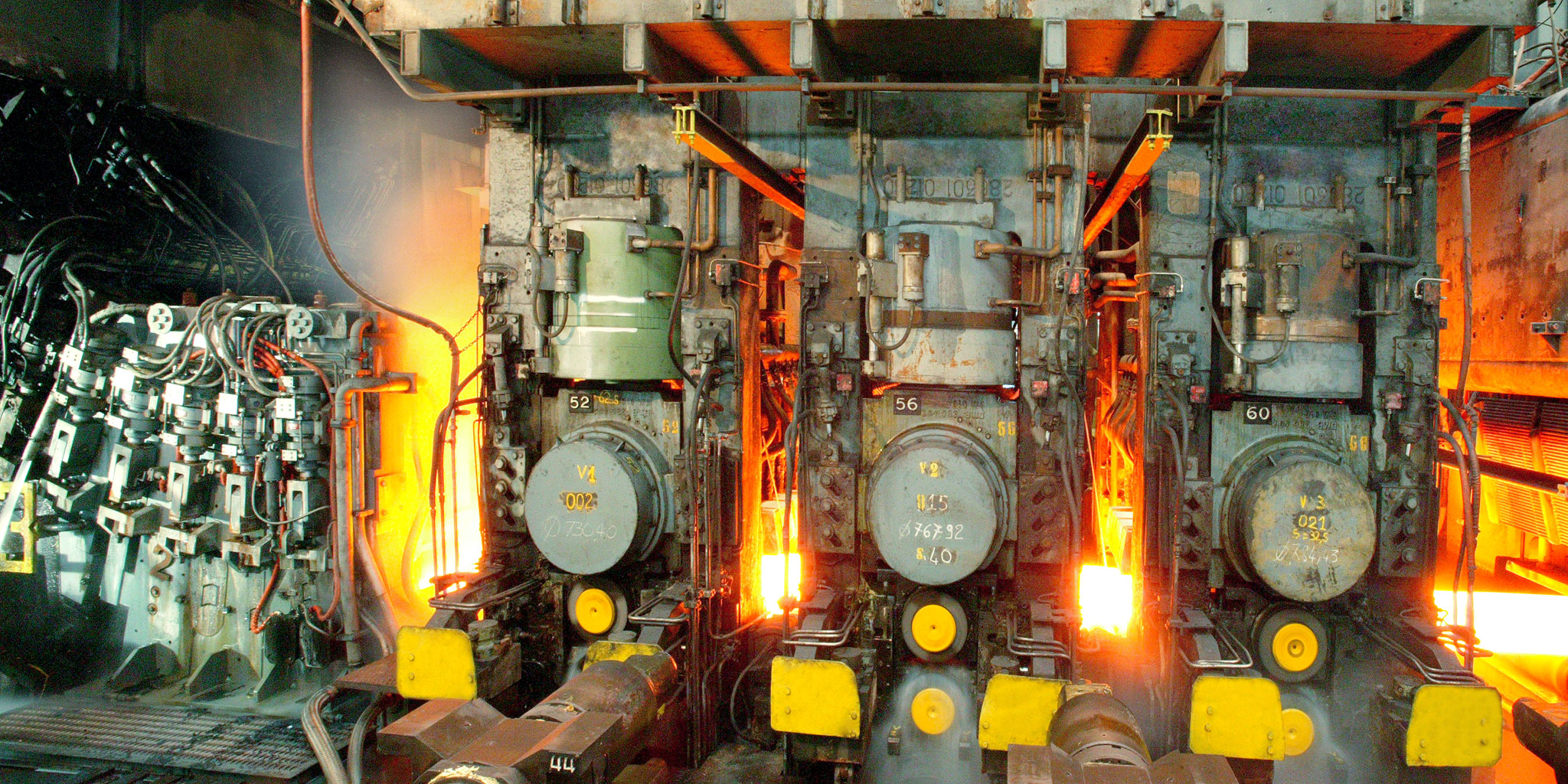

The production cycle of ISP and ESP starts with the casting of a thin slab (75/100 mm) directly reduced with a liquid core to a thickness of 55/90 mm and fed in-line to a roughing mill which reduces it to a very thin gauge (about 10/12 mm) and is subsequently fed to the finishing mill to obtain the final thickness.

The first process phase, together with a limited heating phase achieved through an induction furnace, differentiates Arvedi technology from other thin slab technologies and characterises the process due to the high product quality and the particular attitude to the production of high strength thermo-mechanical thin gauge (0.8 mm) steel grades.

In 1995, once the main phase of the process technology development was finished, the project’s initial production targets were exceeded and the production structure was progressively improved through an increase in melt shop capacity and the installation in 1997 of the fifth rolling stand in the finishing mill.

1998 saw the start-up of the pickling plant with in-line skinpass, expressly studied for processing thin gauges (1 – 1.2 mm) which in the meantime have become part of normal production for the steelworks.

2000 saw a further increase in melt shop capacity with a modification to the melting furnace and the installation of a second ladle furnace for liquid steel refining.

In 2002 the coil galvanizing plant, specifically studied for special products and able to process high strength and dual phase steels, came on line.

Still in 2002 Acciaieria Arvedi started strip cutting activities with the installation of two slitters, an operation until then carried out exclusively by its subsidiary CSS in Corbetta.

In the course of 2004 the continuous casting and pre-rolling machine was modified in order to raise productivity and take it to about 1.2 million tpy.

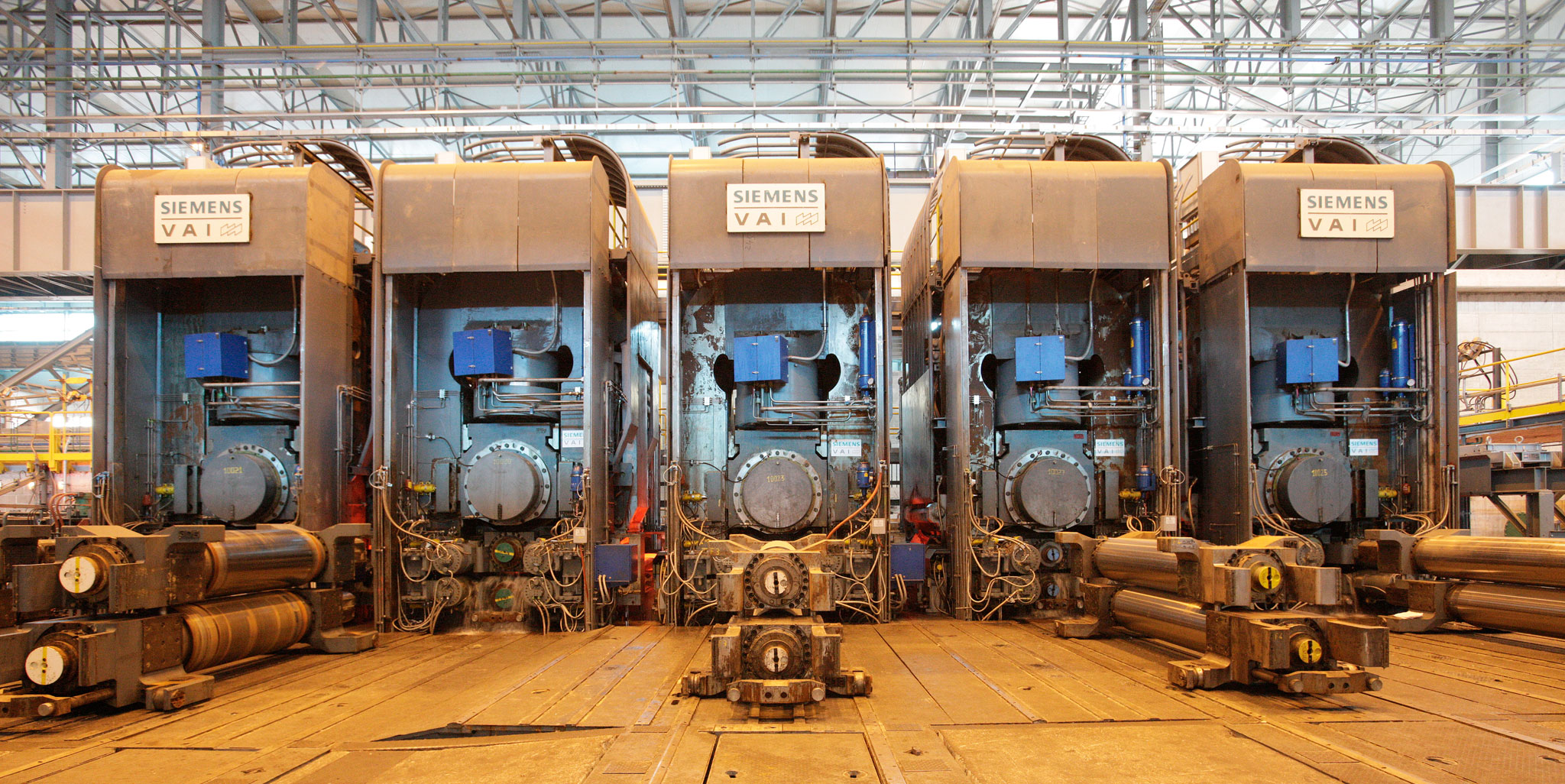

Following a phase of in-depth study and experimentation, in 2006 it was decided to proceed with an important development of production capacity at the works through the installation of a new electric furnace - Consteel - and a new casting and rolling line based on Arvedi ESP® (Endless Strip Production) technology which achieves fully continuous coil production.

With this new technology, started up in the course of 2009, further important objectives have been reached as regards productivity (double that of ISP), products (quality, thicknesses, range of steel grades), production costs and energy saving.

Together with the main hot rolled coil production plant, a new pickling plant for gauges up to 10 mm and a new slitting line suitable for these products were installed.

Following the important increase in production consequent to ESP, the construction of new and powerful finishing lines became necessary: in the course of 2009/2010 continuous pickling and cold rolling plants using the AR-COLD™ system and a galvanizing plant were installed in the North Area which since 2011 have consolidated the full operating capacity.

AR-COLD™ is the first integrated pickling and cold rolling plant for in-line processing of a complete mix of hot rolled coil for the production of cold rolled coil in gauges down to 0.2 mm at a width of 1560 mm ready for galvanizing.

In 2012 a third galvanizing line and two slitting lines able to process ultra-thin gauges were installed in the North Area.

Between 2013 and 2014 two pre-painting lines were installed, in this way completing flat rolled steel verticalization.

In 2015 three more slitting lines were installed taking the total number of slitters in operation to eight, in this way reaching a production capacity of slit material of 1.4 million tpy.

In 2014 the Trieste steelworks became part of the Arvedi Group as Siderurgica Triestina. It is composed of two interdependent sectors: the integrated steelmaking section with a blast furnace; the intermodal logistics terminal and an area to be developed for cold rolling operations.

Since the beginning of 2017 all manufacturing operations of the Trieste site have been transferred to Acciaieria Arvedi.

With the acquisition of the Trieste production site, the Arvedi Group has launched the most important environmental clean-up and modernisation in the history of Italian steelmaking, integrating the electric furnace technology of the Cremona works with the melting of pig iron produced from iron ore at the Trieste site.

In 2016 the cold complex in Trieste started operating to process and finish the hot rolled coils produced by Acciaieria Arvedi in Cremona. The coils are cold rolled to obtain a higher added value as special steels destined for the automotive and construction sectors. The metallurgical complex is structured to develop a production capacity of about one million tpy.

In April 2020 pig iron production operations ceased following an agreement with the local authorities which, in the ambit of a development programme for logistic operations, foresaw the use of some areas formerly pertaining to the ex-ironworks.