Development

The excellent results achieved in terms of both process and product have allowed a subsequent evolution phase to be developed which, on the basis of preliminary studies and tests, allow even better products to be obtained and even lower costs, for the first time in the world achieving casting and rolling in a fully continuous phase.

The product sees minimum gauges lower than current ones, a wider range of high strength steels obtained through thermomechanical rolling and, thanks to the higher casting speeds, plant simplification with higher productivity and lower investment costs.

Overall, therefore, a significant rise in competitiveness.

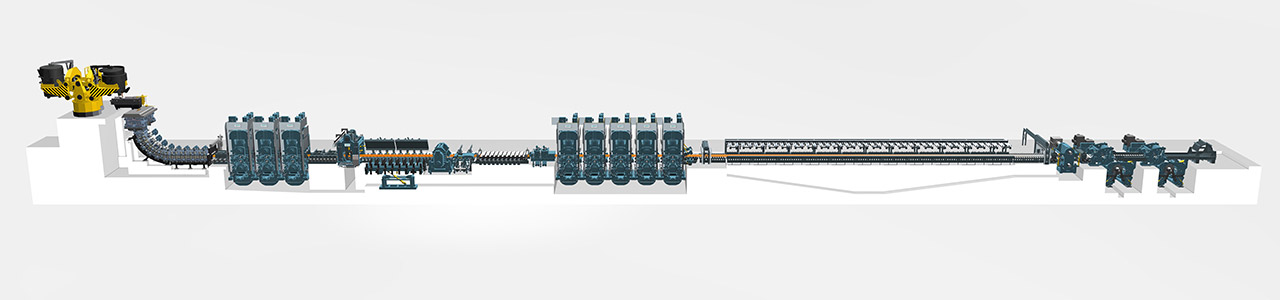

The study and design of a new, even more compact version of the plant, with twice the productivity, operating and investments costs practically halved and higher production and quality performances, were completed in the course of 2007, leading to the construction of a second production line fitted with its own melt shop and the new line based on Arvedi ESP (Endless Strip Production) technology.

Commissioning of the plant was concluded in the second half of 2009.