ISP-ESP Production Process

Arvedi process technology for coils is based on casting thin slabs rolled in-line and is protected by numerous patents, covering the most important industrialised countries, regarding both the technology as a whole and the single plant components.

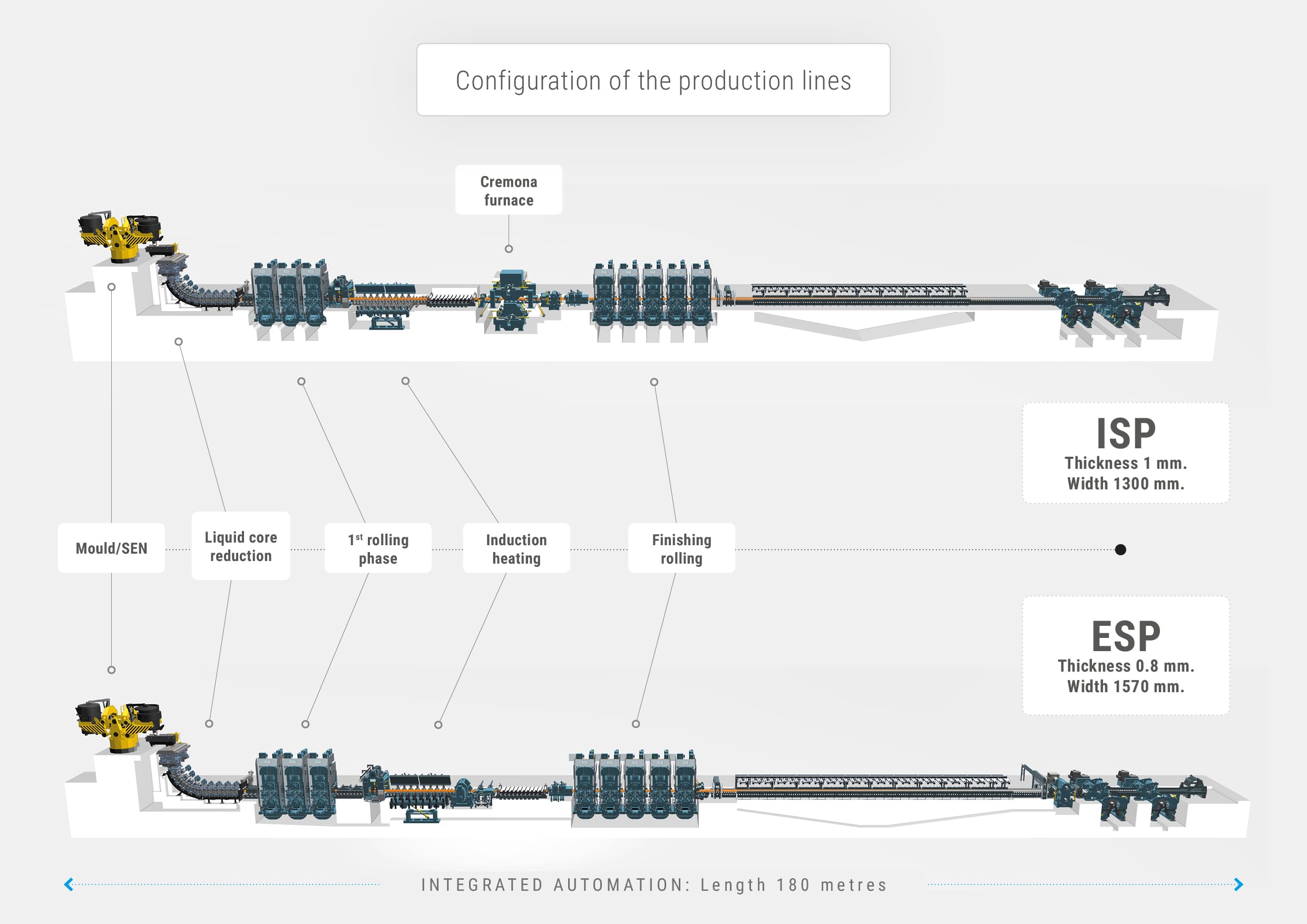

In a single, extremely compact cycle the production line transforms the steel, produced in an electric furnace or converter, into quality thin gauge steel coils which conventional plants and other thin slab technologies were unable to produce or produce at non-competitive costs. The direct transformation of the liquid steel is obtained in only 180 metres and 15 minutes through in-line casting and rolling, exploiting the energy content of the liquid steel and its high plasticity at high temperatures.

CASTING AND ROLLING PHASE

The liquid steel is cast into a thin slab through the “mould system”, patented by Arvedi, in order to obtain the best quality characteristics with a high level of production reliability. The thin slab leaving the mould is reduced in thickness while the core is still liquid and is rolled directly at high temperatures to obtain a high precision intermediate bar with a homogeneous structure. Directly connecting casting and rolling is a fundamental innovation and the key point of the new process technology.

HEATING PHASE

The intermediate bar, heated in the induction furnace (the world’s first example for thin slabs) for ISP is collected in the Cremona furnace, which is specifically fitted with a mandrel in order to coil bars in gauges below 18 mm, and make the temperature homogeneous, while for ESP it is directly charged into the finishing mill.

FINISHING ROLLING PHASE

The pre-rolled strip, after descaling, is charged directly into the finishing mill, achieving casting and rolling in a fully continuous phase. It is reduced to the final gauge by the finishing mill which operates at constant speed and temperature so as to obtain the best product characteristics. The strip is cooled on the run-out table to give the steel the desired mechanical and structural characteristics and immediately wound on the downcoiler.

Thanks to these production technologies, devised and built for the first time in the world on the ideas developed inside the Arvedi Group, the product has excellent qualities, energy consumption is very low and large volumes of hot rolled ultrathin gauges in all steel grades, even high strength ones, can be produced directly.