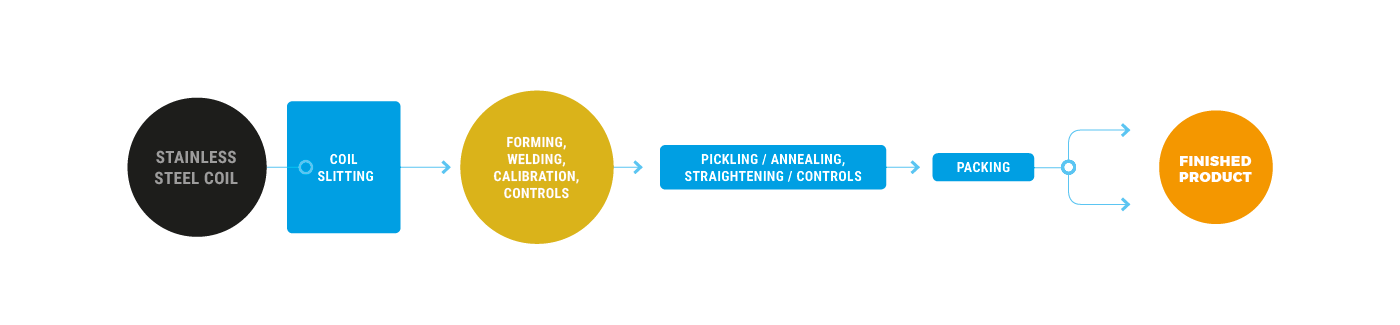

Production process

ILTA Inox produces stainless steel welded tubes in diameters from 10 to 1000 mm and wall thicknesses up to 8 mm. The raw material comprises hot and cold rolled stainless steel coils.

The coils are cut on a special slitting line to produce strip in widths corresponding to the desired circumference of the tube to be produced.

The strips, loaded onto the longitudinal forming and welding lines, are turned and curved through a series of paired rolls to assume a semi-closed circular section with edges touching.

Continuous welding is carried out using Laser techniques, closing the section and creating the tube.

The Laser welding method enables high productivity levels while maintaining the same quality levels provided by TIG techniques.

Depending on the specified production methods, the tube goes from the forming and welding line to the annealing or pickling lines and to the final non-destructive test depending on the customer's intended application.