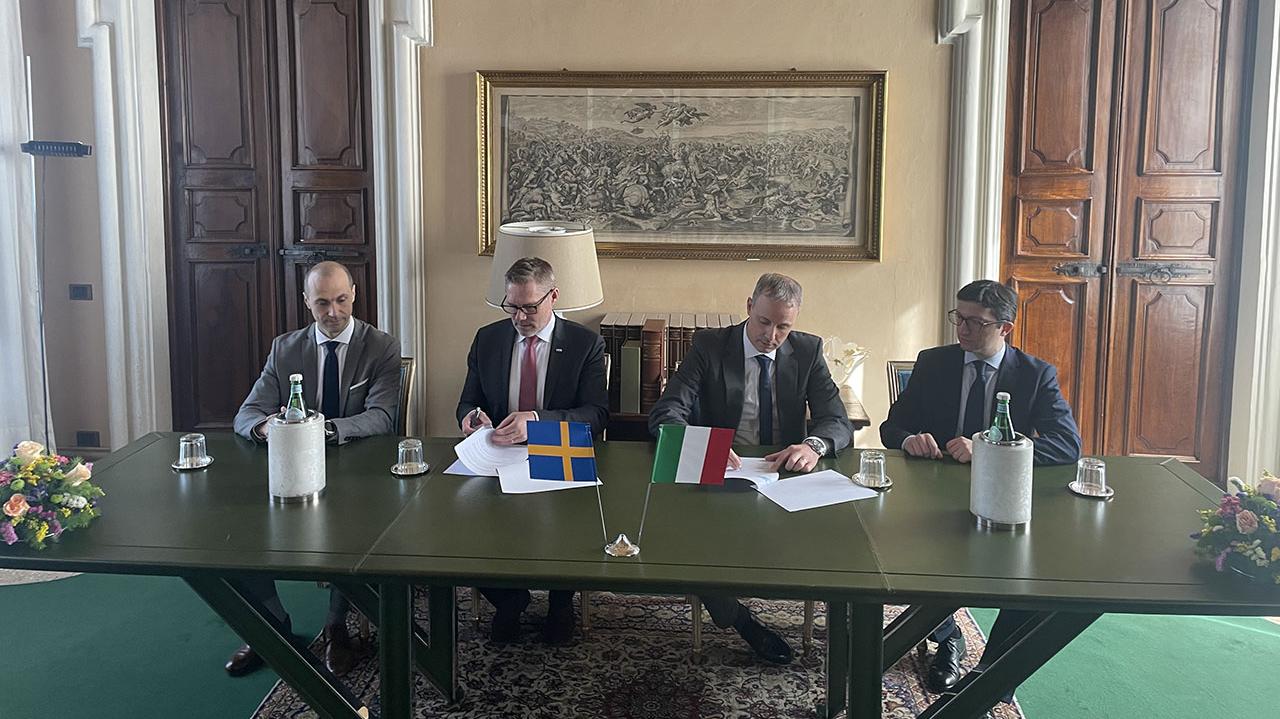

The Italian steelmaker Acciaieria Arvedi and the global automotive safety systems provider Autoliv have signed a cooperation agreement for the supply of Arvzero™, the carbon neutral steel produced from recycled scrap and with electric power 100% certificated from renewable sources.

Arvzero™ is a steel produced using the revolutionary Arvedi ESP™ technology, the fruit of over 30 years of study and research & development, based on electric furnace production cycle, charged with recycled scrap, to achieve the goal of sustainable steel.

Acciaieria Arvedi, part of the Arvedi Group, has managed to reach high levels of environmental sustainability by decarbonizing the steel production cycle. Acciaieria Arvedi wishes to be a reliable partner for all companies which intend to create a green supply chain.

Autoliv is the worldwide leader in automotive safety systems. Autoliv designs, develops, manufactures, and markets automotive safety systems such as airbags, seatbelts and steering wheels for all major automotive manufactures in the world as well as additional mobility safety solutions.

“This agreement,” said Arvedi representative Andrea Brambilla, Automotive Key Account Manager, “is an important milestone of the partnership between our companies. With the Arvzero™ supplies, our commitment is to support Autoliv not only in the decarbonization of the supply chain, but also in increasing the recycled content of their products”.

“This important agreement,” continued the Arvedi representative, “is a further recognition of all our efforts in innovation and sustainability and it witnesses the growing introduction of Arvzero™ steel to the automotive value chain.”

“We are continuously developing and producing products in a resource-efficient way while limiting our environmental impact,” said Cosmin Bakai, Global Raw-Material Area Director, Autoliv. “The collaboration with Acciaieria Arvedi will be a significant step in our efforts to reduce greenhouse gas emissions in our products by utilizing low-emission steel and increasing the recycled content in the material, to achieve our goal of net-zero emissions across our supply chain by 2040.”